Rent-All is a Dutch leading rental company of rigging, lighting, audio and video equipment. From their 5 establishments in the Netherlands, Belgium and Germany, they deliver equipment to theatre and television studios, fairs and festivals across Europe. With a fleet of material of +/- 260.000 rental items, they were looking for an automatic detection system which informs them about the location of their articles, the state they are in and the turnaround time per rental item. After a successful proof of concept and pilot project, Aucxis was engaged to streamline the entire process of outgoing and returning rental materials.

Challenge

Because of the huge fleet of material, the manual registration of the incoming and outgoing movements of the rental materials was a time-consuming and errorprone process:

- Where are the items located?

- What state are they in?

- What is their turnaround time?

- How to accurately and efficiently register the incoming and outgoing movements?

Therefore, Rent-All was looking for an automatic detection system which informs them about the location of their articles, the state they are in and the turnaround time per rental item. Furthermore, the turnkey solution needed to guarantee an interaction with the software of their own ERP package.

Solution

After a successful proof of concept and pilot project, Aucxis was responsible for streamlining the entire process of outgoing and returning rental materials.

Technology and tag selection

Auxcis opted for the worldwide RFID standard UHF Gen2, among others because it enables bulk reading at a large reading distance. For the tag selection, Aucxis has worked experimentally with various hard and label tags. The type was determined per rental item in function of the surface upon which it needed to be mounted and the practical mounting possibilities. Materials such as trusses, speakers and mixing consoles are often visible on stages. The tags cannot be mounted just anywhere on the item and the functioning must be guaranteed at all times. Specifically for the identification of the trusses, preference was given to the Confidex Ironside Slim long-range on-metal tag.

RFID gate at automatic warehouse

The headquarters in Bemmel has an automatic high-bay warehouse, in which the racks are located as close as possible to each other. That is why the pallets are not put in their place by a forklift but by an internal robot of the automatic warehouse, which enables working at higher level and more safely and also creates additional storage space. Rent-All’s WMS informs the user on the exact location of the pallets, but thanks to the interaction between the application of the automatic warehouse and the Aucxis middleware HERTZ, the customer also knows which articles are located on the pallet.

Mobile RFID gates at the loading docks

During the loading and unloading of the orders, all rental materials – so both the goods for the customers as well as the materials shuttling between the establishments – pass first through an RFID gate. The RFID gates with integrated readers and antennas register all passing tags and send the information to Rent-All’s ERP system via the Aucxis middleware HERTZ. Impinj R420 readers were being used.

Rent-All built a frame around each two fully equipped RFID units to be able to move the gates. They always remain in the same establishment, but their loading dock can be changed.

Auxcis delivered one RFID gate per two loading docks, which means 10 for the headquarters in Bemmel (the Netherlands), 6 for Lier (Belgium), 4 for Amsterdam (the Netherlands) and Castrop-Rauxel (Germany) and 2 for the smallest site in Nürnberg (Germany).

WMS software

Aucxis also delivers the required WMS software which contains, among others, a validation of the materials upon delivery and return, digital support of the order pickers and a real-time link with the company’s existing ERP package.

Result

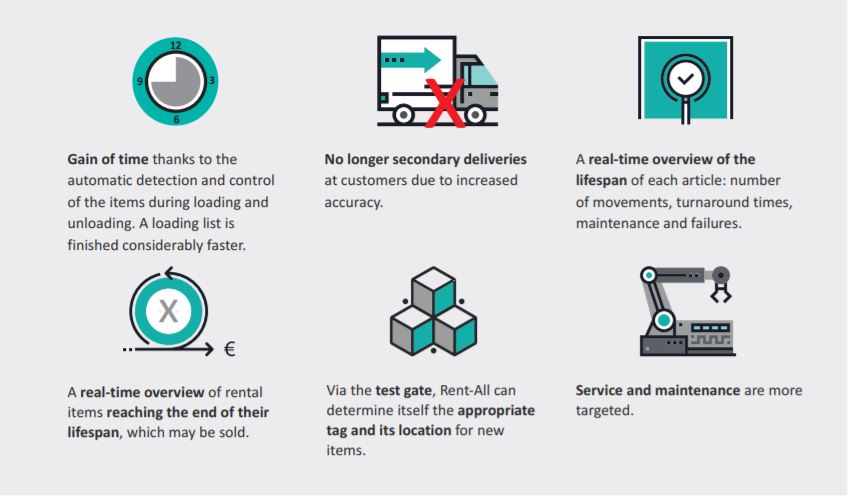

- Gain of time. Thanks to the automatic detection and control of the items during loading and unloading, a loading list is finished considerably faster;

- No more secondary deliveries at customers due to increased accuracy;

- A real-time overview of the lifespan of each article: number of movements, turnaround times, maintenance and failures.

About

Aucxis offers powerful and flexible RFID solutions through hardware installation and development of RFID middleware and interfaces. As an independent integrator, Auxcis helps customers define and aquire the RFID components best suited to meet customer objectives.