Wattro GMBH is a company that helps businesses gain complete transparency and control over their entire inventory of tools and equipment. For example, this applies to companies in the trades, manufacturing industry and numerous other sectors.

Their solution tackles the common challenges faced by companies with numerous tools: time wasted searching for equipment, losing track of assets and difficulty managing maintenance schedules.

Challenge

Companies with a large number of tools and equipment, particularly those with employees who take tools to off-site projects, often struggle with chaotic management systems, leading to lost or misplaced assets, interrupted workflows and increased costs due to the need for replacements. Traditional tracking methods, required manual scanning of QR codes for each tool, a process often overlooked by workers focused on completing their jobs rather than on administrative tasks. This led to a chaotic management system, with tools getting lost, no accountability for damaged items, and a general lack of organization. The main issue was the impracticality of existing solutions that relied heavily on manual input, which was often neglected, resulting in inefficiency and increased operational costs.

Solution

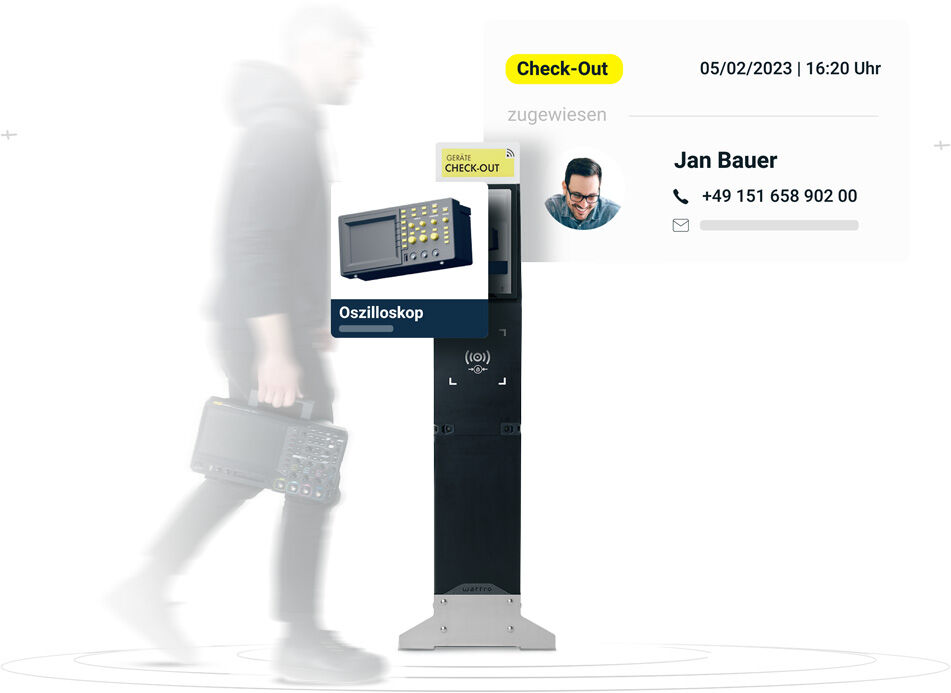

Wattro's solution revolutionizes asset tracking with an RFID-based system that automates the entire process. The cornerstone of Wattro's innovation is its RFID scan terminal, powered by the TSL 3417 module, which automatically recognizes tools as they are taken out or returned. This integration simplifies the check-in and check-out process to a simple tap, eliminating the need for manual scanning and reliance on smartphones, thereby streamlining the asset management process significantly.

This system consists of a cloud-based platform, accessible through both smartphone and desktop apps, where all tool-related information is meticulously stored and readily accessible. A patented algorithm enhances the system's precision, utilizing the RSSI (Received Signal Strength Indicator) and phase values from the TSL 3417 module for unparalleled accuracy in tool identification.

Their RFID asset management solution provides complete transparency over the entire inventory, accessible from anywhere, at any time. It automatically detects which tools are leaving the warehouse and emits a loud warning tone if the check-out is forgotten. Tools are recognized via radio frequency as they leave the warehouse, enabled by marking the inventory with RFID tags.

To track a variety of tools, Wattro uses a set of five standard tags designed for both metal and non-metal items, considering size and application. These tags, including the XERAFY Cargo outdoor and XERAFY Flex tag, guarantee comprehensive asset tracking. Each tool is equipped with two strategically placed tags for reliable detection.

The Wattro terminal is positioned at the warehouse exit, identifying the RFID tags on devices and machinery. This setup ensures full control over everything that enters or leaves, streamlining the asset management process.

Wattro chose the TSL 3417 Four Port RAIN RFID Reader Modules for their cost-effectiveness, advanced features and reliability. Excellent customer support made integration smooth and operations seamless.

Result

The implementation of Wattro's RFID solution has significantly benefited its clients, notably in the craft industry, by drastically reducing the time spent searching for tools, from an average of 5-10 minutes per worker per day to about two minutes. Moreover, it has addressed the issue of losing tools and the associated costs, with businesses saving costs annually on unnecessary replacements. The system's efficiency and ease of use have been well-received, with companies like Flex and Heinrich Schmid among Wattro's satisfied clients, showcasing the solution's applicability across different scales and sectors.

Conclusion

Wattro's introduction of RFID technology for managing assets has created a new benchmark not just in the craft sector, but in other industries as well. By automating the tracking process and ensuring efficient management of tools and equipment, Wattro has not only improved operational efficiency but also helps achieve substantial cost savings. The comprehensive visibility over inventory, combined with real-time updates and streamlined device requests, minimizes delays and optimizes the management of inspections and certifications.

Used Cisper products: